|

Micro-scale polymer processing (MUPP)

The micro-scale polymer processing (MUPP) project co-ordinates UK expertise in molecular rheology and processing of polymeric materials. The project is a direct response to repeated requests from UK industry for a systematic, generic understanding of molecular variables in polymer processing. This understanding is essential to allow industry to optimise process and product properties, and permit UK companies to remain competitive in an increasingly competitive global marketplace.

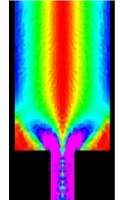

The scientific programme for MUPP involves the careful preparation of well-defined materials, which are analysed and the results compared to model calculations. This allows semi-scale industrial processes, such as extrusion and injection processing, to be directly compared with mathematical and computational modelling protocols. This links processing parameters, and the past process history of the polymer, with molecular properties. The final objective is to parameterise polymer process outcomes (such as die entry/exit characteristics, and solidification under draw) in terms of molecular weight distribution and long chain branching. To do this the core academic programme has been geared to effect a technology transfer to our industrial collaborators. They in turn feedback scale results to the academic programme, which is continually refined to meet these new challenges. For more details see the MUPP website. |

|

|

|

|

© The Polymer IRC 2004, design www.cookandkaye.co.uk /

Webmaster /

Disclaimer /

Privacy The IRC includes the University of Bradford, the University of Durham, the University of Leeds and the University of Sheffield. | |