High efficiency value-added bulk recycling of polymers by solid state shear milling

Polymer IRC, University of Bradford, UK and Sichuan University, China

This UK-China joint project is one of 4 funded by EPSRC-NSFC in the area of Low Carbon Manufacturing.

Overall, this study aims to provide world-leading technologies for scalable, value-added efficient recycling of difficult-torecycle bulk polymer waste streams.

Specifically:

1. We will design and develop new multi-stage shear-milling equipment which exerts primarily shear force to realize ultrafine pulverization, de-crosslinking and solid-state compatibilization at ambient temperature for various major, difficult-to-recycle polymer waste streams, and establish efficient, energy-saving and clean key equipment for high volume waste plastics processing.

2. We will clarify the mechanisms of ultrafine pulverization, homogenization modification, mechanochemical activation and compatibilization of mixed or compound plastic wastes and de-crosslinking of crosslinked polymer wastes leading to thermo-processability, through the developed solid-state shear milling equipment. The industrial-scale recycling of bulk difficult-to-recycle polymer wastes, such as multi-layered films, mixed plastic, tyres and fibre reinforced plastics and composites will be more fully established.

3. We will reprocess ultrafine recyclate powders by advanced polymer processing technologies (e.g. rotary extrusion processing, dynamic vulcanization, solid-phase deformation and precision moulding technologies) in China and the UK, regulating the morphology and structure of polymeric materials during processing. The UK team will focus on reprocessing (melt and solid phase), including in-process metrology, of the various recycled polymer waste powders obtained from S3M, and evaluate the effect of particle size and distribution on the processablity via processing rheology, and on mechanical properties of recycled materials.

4. We will fabricate high-value-added waste-polymer-based demonstrator products for applications including irrigation and water conservancy, road construction, outdoor facilities, building materials.

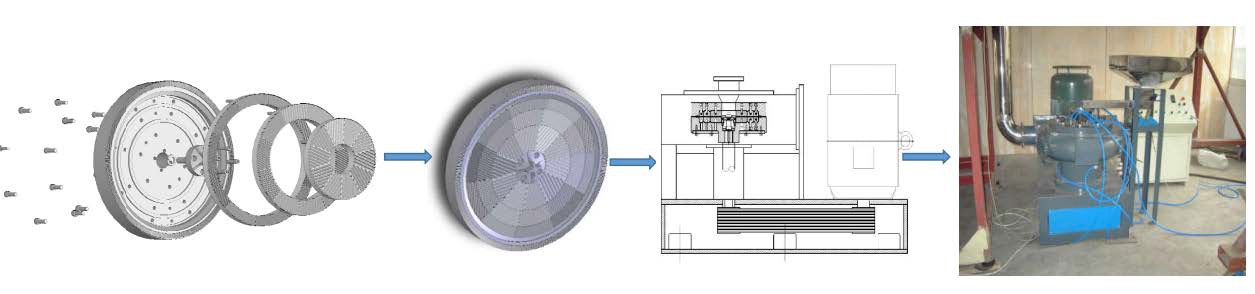

prototype solid state shear milling equipment at Sichuan University, used in mechano-chemical milling of a range of polymer waste streams

Over 300 million tonnes of plastic is produced annually and this is expected to double over the next 20 years. Plastics have become vital materials in many aspects of everyday life but the generation of plastics solid waste (PSW) is becoming an increasing problem, for example 8 million tonnes of plastic waste finds its way into the oceans each year, having a huge impact on marine ecosystems. Some relatively clean and easy to separate types of waste plastics can be recycled economically, such as drinks bottles, and levels of recycling are increasing but many polymeric materials are much more difficult to recycle, for example composites containing different materials of polymers which cannot be re-melted such as rubber tyres and printed circuit boards. As such there is an urgent need worldwide to develop new technically and economically feasible methods to recycle these types of materials. This aligns with the concept of a circular economy which seeks to keep products and materials in use and design out waste and pollution. Our joint UK-China team aims to develop an industrial scale continuous process to successfully recycle and remanufacture currently difficult to recycle bulk waste streams, with high efficiency. A continuous milling process will be developed to break down solid polymeric waste into fine powders with controlled properties, which can then be reprocessed into value-added products. We will perform experiments to understand the mechanisms of the milling process and how these can be opitimised for particular waste streams. We will characterise the materials produced and examine different ways of turning these powders into useful, value-added products We combine unique skills and strengths of our Chinese and UK groups to address key issues facing both of our countries - effectively reducing the significant amount of plastic waste with efficient routes to re-use. This proposal builds on the highly successful research collaborations over the last decade between the world-class research laboratories of the Polymer IRC at Bradford and Sichuan University State Key Laboratory for Polymer Materials Engineering (SKLPME), an important and international award-winning part of our RCUK Bradford Science Bridges China platform.

Team:

Polymer IRC: Prof Adrian Kelly (PI); co-I’s - Prof Phil Coates, Prof Hadj Benkreira, Dr Fin Caton-Rose, Prof Ben Whiteside

Sichuan University: Prof Canhui Lu, Prof Qi Wang, Prof. Xinxing Zhang, Prof Yinghong Chen, Assoc Prof Shibing Bai.